In the intricate world of railway engineering, the phenomenon of rail vibration harmonics presents both a formidable challenge and a tantalizing opportunity. The resonant frequencies inherent in steel rails, if left unmanaged, can lead to accelerated wear, noise pollution, and even structural failures. Yet, when properly understood and harnessed, these same vibrations hold the potential to enhance monitoring systems, improve safety protocols, and even contribute to energy harvesting initiatives. This dual nature of rail vibrations—as both a destructive force and a beneficial resource—forms the core of contemporary research and development efforts across the globe.

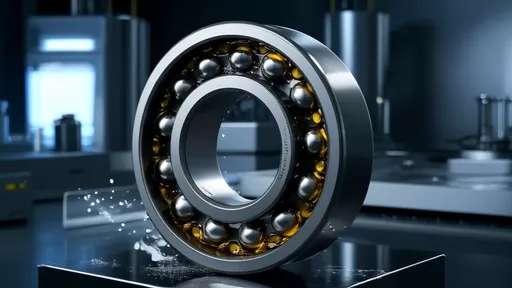

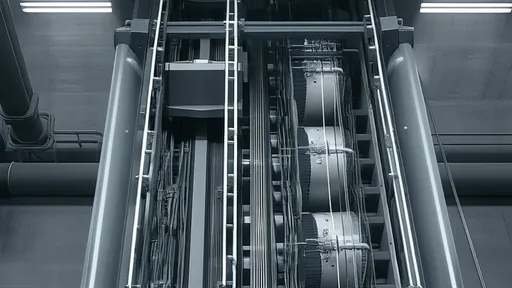

The fundamental issue stems from the fact that steel rails are not static entities; they are dynamic components that respond to the loads and forces imposed by moving trains. As wheels pass over the rails, they induce vibrations that propagate along the track structure. These vibrations occur across a spectrum of frequencies, but it is the resonant frequencies—those at which the rail naturally oscillates with greater amplitude—that are of particular concern. At resonance, even small, repetitive forces can lead to large vibrational responses, exacerbating issues such as fatigue cracking, loosening of fasteners, and increased maintenance requirements. Understanding the specific resonant frequencies of a given rail section is therefore critical, as these frequencies are influenced by factors including rail geometry, material properties, support conditions, and the underlying track foundation.

Historically, the primary approach to managing rail vibrations has been suppression. Engineers have developed a suite of damping technologies designed to dissipate vibrational energy before it can build to destructive levels. One common method involves the use of tuned mass dampers—auxiliary devices attached to the rail that are designed to oscillate out of phase with the harmful vibrations, thereby canceling them out. Another widespread technique is the application of constrained layer damping materials. These viscoelastic materials, when bonded to the rail, convert mechanical vibrational energy into heat, effectively damping the oscillations. The development of advanced elastomers and composite materials has significantly improved the efficacy and longevity of these solutions. Furthermore, optimizing the design of rail pads and sleepers (ties) to provide greater inherent damping has proven highly effective. The continuous refinement of these suppression technologies represents a major front in the battle against track degradation and noise.

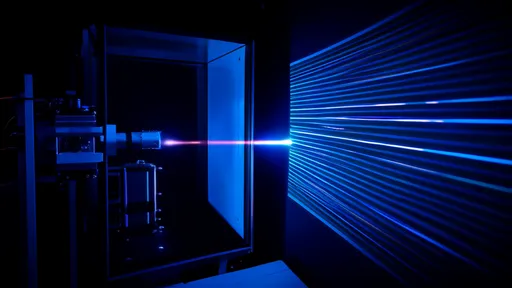

However, the narrative is shifting from mere suppression to intelligent utilization. Researchers are now exploring how the energy from rail vibrations can be captured and put to work. The concept of energy harvesting on railways is gaining traction. Piezoelectric materials, which generate an electric charge in response to mechanical stress, can be embedded in or attached to the track infrastructure. As trains pass over these sections, the vibrations compress the piezoelectric elements, producing small amounts of electricity. While the power generated from a single vibration is minimal, the cumulative effect from thousands of train passes each day on a busy network could be substantial. This harvested energy has potential applications in powering trackside sensors, wireless monitoring equipment, and signaling systems, reducing reliance on external power sources and batteries, and enhancing the sustainability of rail operations.

Perhaps the most promising application of understood vibration harmonics is in the realm of condition monitoring and predictive maintenance. The vibrational signature of a rail segment is a rich source of data about its health and the vehicles passing over it. By deploying networks of accelerometers and other vibration sensors along the track, operators can continuously monitor the dynamic response of the infrastructure. Advanced signal processing algorithms and machine learning models can analyze this data in real-time to detect anomalies. A shift in resonant frequency, for instance, could indicate a developing crack or a loss of support stiffness. Changes in the harmonic response could signal wheel flats or other defects on passing rolling stock. This shift from scheduled, time-based maintenance to condition-based, predictive maintenance allows for interventions to be made precisely when needed, maximizing both safety and resource allocation.

The journey from fundamental research to practical implementation is complex and requires a multidisciplinary effort. It involves not only mechanical and civil engineers but also experts in materials science, data analytics, and electrical engineering. Large-scale field trials are essential to validate laboratory findings under real-world conditions, accounting for variables like temperature fluctuations, weather, and varying train types and speeds. The economic viability of these technologies, particularly for energy harvesting systems, must be carefully assessed to ensure they offer a tangible return on investment for rail operators. Nonetheless, the progress made in recent years is undeniable, pointing towards a future where rail networks are not only quieter and more durable but also smarter and more self-sufficient.

In conclusion, the study of rail vibration harmonics is a vivid example of turning a problem into a solution. The resonant frequencies that once represented a threat to the integrity and quiet operation of railway systems are now being systematically countered with sophisticated damping technologies. More impressively, they are being co-opted as a valuable source of both energy and information. As research continues to advance, the harmonious management of these vibrations will undoubtedly play a central role in building the safer, more efficient, and more sustainable railways of the future. The rails themselves are becoming a responsive, intelligent component of the transport ecosystem, speaking a language of vibrations that we are finally learning to interpret and command.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025