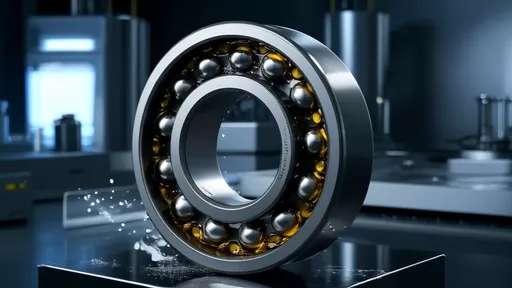

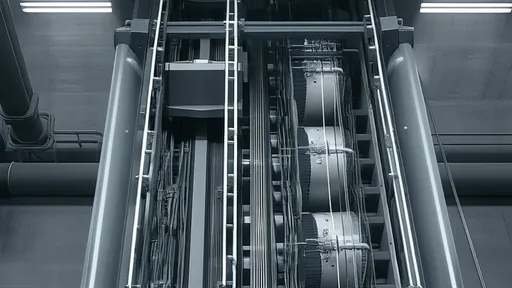

In the intricate world of mechanical engineering, the study of bearing fluid dynamics stands as a cornerstone for understanding and enhancing the performance of rotating machinery. A recent groundbreaking study, titled "Fluid Motion in Bearings: Experimental Validation of Lubrication Theory for Steel Ball Rolling," has provided profound insights into the complex interactions between rolling elements and lubricants within bearing systems. This research not only reaffirms long-standing theoretical models but also introduces nuanced observations that challenge and refine our comprehension of hydrodynamic and elastohydrodynamic lubrication regimes.

The research meticulously examines the behavior of lubricating fluids as steel balls roll between inner and outer races, a scenario fundamental to ball bearing operation. Utilizing advanced high-speed imaging and precision sensors, the team captured real-time data on fluid film formation, pressure distribution, and flow patterns under varying loads, speeds, and lubricant viscosities. Their experimental setup allowed for unprecedented visualization of the micro-scale fluid dynamics that occur in the narrow gaps of rolling contacts, where pressures can soar to extreme levels, significantly altering the lubricant's properties.

One of the most significant findings centers on the validation of classical Reynolds equation-based models for predicting film thickness in hydrodynamic lubrication. The experiments demonstrated remarkable agreement with theoretical predictions under moderate operating conditions, confirming the reliability of these models for engineering applications. However, under high-load and high-speed scenarios, the study observed deviations that highlight the limitations of assuming constant lubricant viscosity. The researchers documented instances where lubricant starvation or thermal effects led to thinner films than anticipated, emphasizing the need for more sophisticated, temperature-aware models in predictive maintenance and design.

Furthermore, the study delves into the transition zone between hydrodynamic and elastohydrodynamic lubrication (EHL), a critical region where both fluid dynamics and surface elasticity play pivotal roles. The team's data revealed how the lubricant's pressure-viscosity effect becomes dominant under these conditions, causing temporary solidification of the fluid and enabling the formation of ultra-thin but resilient films that prevent metal-to-metal contact. This phenomenon was captured with exceptional clarity, showing how the elastic deformation of the rolling elements and races works in concert with the lubricant to distribute loads and minimize wear.

Another compelling aspect of the research is its exploration of fluid motion within the bearing cavity itself. Beyond the contact zones, the study analyzed how lubricant circulates, churns, and potentially aerates, which can influence overall efficiency and heat generation. The researchers identified patterns of recirculation and vortex formation that contribute to energy losses and elevated operating temperatures. These insights are invaluable for designing next-generation bearings with optimized lubricant flow paths to reduce churning losses and improve thermal management.

The implications of this work extend far beyond academic interest. For industries reliant on high-performance machinery—such as aerospace, automotive, and energy—these findings offer a pathway to enhanced reliability and longevity of components. By validating and refining lubrication theories, engineers can develop more accurate predictive tools for bearing life, optimize lubricant selection, and implement maintenance strategies that preempt failures. The study also underscores the importance of considering real-world operating conditions, rather than relying solely on idealized models, when designing critical systems.

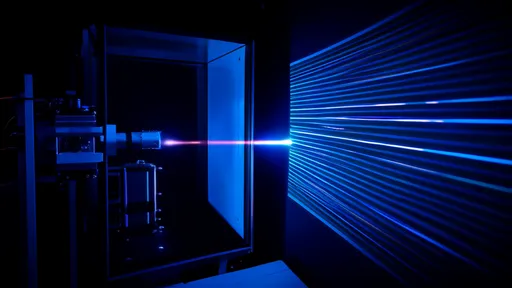

In addition to its technical contributions, the research methodology sets a new standard for experimental rigor in tribology. The integration of non-intrusive measurement techniques, such as laser-induced fluorescence and interferometry, provided data with minimal disturbance to the system being observed. This approach allowed for a more authentic representation of in-service conditions, capturing transient effects and nonlinear behaviors that are often smoothed over in simulations.

Looking ahead, the authors suggest several avenues for future work, including the investigation of novel lubricant formulations with nano-additives, the impact of surface textures on fluid retention, and the dynamics of hybrid bearings incorporating ceramic elements. They also advocate for the development of multiphysics models that couple fluid dynamics with thermal, structural, and even acoustic analyses to create a holistic understanding of bearing performance.

This study marks a significant milestone in the field, bridging theoretical elegance with practical relevance. It not only confirms the enduring value of foundational lubrication theories but also pushes the boundaries of our knowledge, revealing the subtle complexities that govern the behavior of fluids in motion within bearings. As machinery continues to evolve toward higher speeds, greater loads, and increased efficiency, such insights will be indispensable in driving innovation and ensuring operational excellence across countless applications.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025