The manufacturing landscape is witnessing a quiet yet profound revolution, one that is reshaping how industries conceive and produce complex metal components. At the heart of this transformation lies Metal Injection Molding (MIM), a sophisticated powder metallurgy process that is rapidly becoming the go-to solution for the high-volume production of intricate, high-performance parts. This technology, often described as a hybrid between plastic injection molding and conventional powder metallurgy, is unlocking design freedoms and economic efficiencies previously thought unattainable for mass-produced metal items.

The MIM process begins with the creation of a homogeneous feedstock. Extremely fine metal powders, typically less than 20 micrometers in size, are meticulously blended with a thermoplastic binder system to form a granulated compound. This critical first step ensures a uniform distribution of metal particles within the polymer matrix, which is fundamental to achieving consistent and reliable final properties. The choice of metal is vast, encompassing everything from stainless steels, low-alloy steels, and tool steels to exotic materials like titanium, tungsten, and various nickel-based superalloys, catering to a diverse range of application requirements.

This prepared feedstock is then fed into a standard plastic injection molding machine. Here, it is heated until it achieves a viscous, paste-like consistency and is then injected under high pressure into a precision-machined mold cavity. This stage is where MIM's greatest advantage is realized: the ability to form highly complex geometries—including thin walls, sharp corners, undercuts, and intricate internal features—that are either impossible or prohibitively expensive to create through machining, casting, or traditional powder compaction. The resulting part, known as a "green" part, is a precise shape replica but is fragile at this stage, held together primarily by the binder.

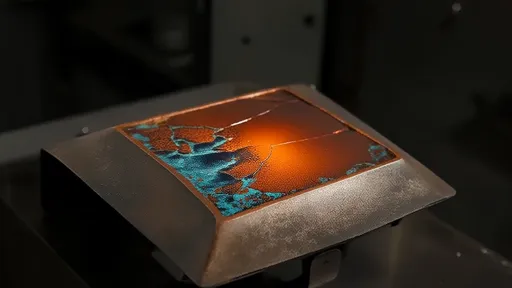

Following molding, the primary challenge is the removal of the binder without compromising the delicate powder structure. This is achieved through a carefully controlled two-step process. First, the green parts undergo debinding, where a significant portion of the binder is removed, often using a solvent extraction method or a catalytic process. This leaves a highly porous structure called a "brown" part, which possesses just enough handling strength to be moved to the next stage. The remaining binder is then eliminated during the subsequent sintering phase.

The sintering process is where the magic truly happens, transforming the fragile brown part into a solid, fully dense metal component. Parts are heated in a precisely controlled atmosphere furnace at temperatures high enough to cause the metal powder particles to fuse together through solid-state diffusion, but carefully kept below the material's melting point. This results in significant shrinkage, typically isotropic and around 15-20%, which is accurately predicted and compensated for in the initial mold design. The final sintered component exhibits mechanical properties—such as tensile strength, hardness, and corrosion resistance—that are often comparable to, and sometimes even exceed, those of wrought or machined equivalents.

The economic argument for MIM is compelling, particularly when applied to high-volume production runs. While the initial costs for tooling and process setup can be higher than some alternatives, the per-part cost plummets as volumes increase. This is due to the process's high level of automation, minimal material waste (near-net shape production), and dramatically reduced secondary machining requirements. For complex parts that would otherwise require extensive CNC machining from solid billet or multi-part assembly, MIM offers staggering cost savings, sometimes reducing the price per part by an order of magnitude once production is scaled.

The applications for MIM components are vast and growing, penetrating industries where complexity, performance, and volume intersect. In the medical and dental fields, MIM is indispensable for producing surgical instruments, orthopedic implants, and dental brackets with the required biocompatibility and intricate features. The automotive industry leverages it for fuel system components, turbocharger parts, and safety system mechanisms. Consumer electronics, a sector driven by miniaturization, relies on MIM for tiny, complex hinges, connectors, and casings. Furthermore, the aerospace and defense sectors utilize the technology for lightweight, strong components in guidance systems and armaments.

Despite its numerous advantages, MIM is not a universal panacea. The technology is most economically viable for small-to-medium sized parts, typically weighing less than 100 grams, though larger parts are possible. The high initial tooling cost makes it less suitable for prototyping or very low-volume production. Furthermore, achieving and maintaining tight tolerances can be challenging due to the shrinkage during sintering, often necessitating secondary machining for critical dimensions. Success with MIM requires deep expertise in material science, mold design, and process control to navigate these complexities.

Looking forward, the trajectory of Metal Injection Molding points toward continued innovation and expansion. Advancements in powder production technology are making finer, more spherical powders available at lower costs, enhancing final part properties. Binder systems are becoming more sophisticated, allowing for easier and more environmentally friendly debinding. The range of applicable materials is also broadening to include more ceramics and specialty alloys. As additive manufacturing (3D printing) rises in prominence, a synergistic relationship is emerging, where 3D printing is used for rapid prototyping of MIM molds or even for direct binder application, further accelerating development cycles.

In conclusion, Metal Injection Molding stands as a cornerstone of modern advanced manufacturing. It has successfully democratized access to complex, high-performance metal components, enabling product innovation across a spectrum of industries. By masterfully combining the design freedom of plastic molding with the integrity and performance of solid metal, MIM has indeed sparked a production revolution for complex structural parts, proving that in the world of manufacturing, complexity and volume are no longer mutually exclusive concepts.

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025