In the world of precision engraving and micro-carving, the choice of tools can make or break an artist's work. Among the most specialized instruments available today is the 0.08mm diamond engraving needle, a tool so fine it borders on the microscopic. This ultra-thin diamond-tipped cutter has gained a cult following among master engravers, miniature sculptors, and even semiconductor technicians who require sub-millimeter accuracy in their work.

The 0.08mm measurement refers to the tip diameter - roughly the thickness of a human hair - with the diamond particle coating providing exceptional hardness and wear resistance. Unlike traditional steel gravers that dull quickly when working with hard materials, diamond micro blades maintain their edge through extensive use. Japanese manufacturers in particular have refined the production of these tools to near-perfection, though several European and American brands now offer competitive alternatives.

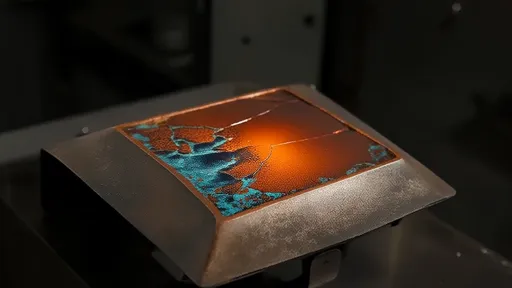

Working with such delicate instruments requires not just steady hands but specialized magnification equipment. Most users operate under 10x to 40x magnification, with some extreme precision work demanding microscope assistance. The diamond tip allows for crisp lines in materials ranging from soft wax (for jewelry prototyping) to hardened steel (for industrial applications), though its primary use remains in the arts and high-tech manufacturing sectors.

Performance characteristics vary significantly between manufacturers. Premium Japanese models exhibit virtually no tip wobble even at maximum extension from the handpiece, a critical factor when engraving at this scale. The diamond particle distribution also differs - some brands concentrate more abrasive material at the very tip for prolonged sharpness, while others distribute particles more evenly along the shaft for different carving techniques.

Vibration damping proves another crucial differentiator. High-end models incorporate specialized alloys in their construction to minimize harmonic vibrations that can ruin microscopic details. Some professional engravers modify their tools with custom dampening sleeves or even mount them on miniature shock absorption systems when working on particularly vibration-sensitive projects.

Material compatibility represents both the tool's greatest strength and its limitation. While the diamond tip excels on non-ferrous metals, glass, ceramics and certain plastics, it can struggle with some ferrous alloys unless properly lubricated. The extreme fineness of the 0.08mm tip also makes it somewhat fragile against lateral forces - these are essentially push-cut tools rather than all-purpose carvers.

Sharpening and maintenance present unique challenges. Unlike conventional cutting tools that can be resharpened on whetstones or with files, diamond micro blades require specialized equipment for refurbishment. Some manufacturers offer lifetime sharpening services, while others consider the tools disposable after significant wear. The diamond coating typically lasts through 50-100 hours of continuous use before noticeable degradation occurs, depending on material hardness.

Ergonomics play an unexpectedly large role in tool selection. Because micro-carving sessions often last hours, the balance and grip diameter of the handpiece become critical factors. Several manufacturers now offer customizable handles with adjustable weights, and some even provide 3D-printed grips molded to the user's specific hand measurements. These considerations might seem excessive until one experiences hand fatigue during a six-hour engraving session.

The pricing spectrum reflects these variations in quality and features. Entry-level 0.08mm diamond cutters start around $80-120, while professional-grade instruments from top manufacturers can exceed $600 per unit. Some sets targeting industrial users include multiple interchangeable tips at slightly different diameters and angles, with complete kits reaching $2,000-3,000. For serious practitioners, this represents a justifiable investment given the tool's capabilities and lifespan.

Real-world applications continue to expand as the technology improves. Beyond traditional engraving arts, these micro tools now see use in watchmaking for decorating movement components, in electronics for PCB repair, and even in scientific fields for preparing microscope samples. Some dental technicians have adapted them for detailed porcelain work, while forensic investigators employ them for marking evidentiary items with microscopic identifiers.

Future developments may push the boundaries even further. Several research institutions are experimenting with 0.05mm and even 0.03mm diamond tips, though these approach practical limits of structural integrity. Another emerging trend involves laser-assisted micro engraving systems that combine traditional mechanical cutting with precise thermal assistance, potentially extending tool life and expanding compatible materials.

For artisans considering entry into micro-engraving, the 0.08mm diamond cutter represents both an exciting opportunity and a serious commitment. The learning curve proves steep - initial results often disappoint until proper technique develops. However, those who persist discover an entirely new realm of creative possibility, where marks invisible to the naked eye become expressive mediums under magnification. In this specialized world, the difference between adequate and exceptional tools becomes immediately apparent in the quality of work produced.

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025