The world of jewelry manufacturing is witnessing a revolutionary transformation with the advent of nanometer-scale micro-setting technology. This cutting-edge technique enables the precise arrangement of gemstones as small as 0.5mm in diameter, creating breathtaking patterns and designs that were once considered impossible. The marriage of nanotechnology and traditional craftsmanship has opened new frontiers in luxury adornment, challenging the limits of human dexterity and artistic expression.

At the heart of this innovation lies the automated array system that positions microscopic gemstones with atomic-level precision. Unlike conventional setting methods that rely heavily on manual labor, this advanced technology utilizes computer-controlled robotics guided by high-resolution imaging systems. The result is a flawless alignment of stones that creates shimmering surfaces with perfect symmetry, transforming jewelry into miniature works of architectural brilliance.

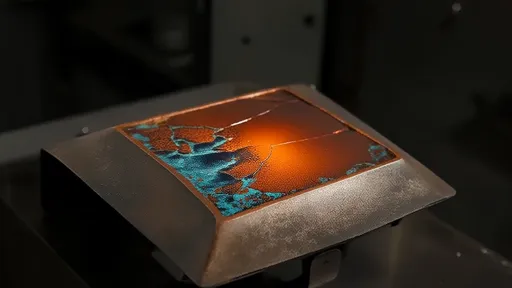

The process begins with specially engineered nanoscale drill bits that create microscopic cavities in the metal base. These receptacles are designed to hold each gemstone at optimal angles for maximum light reflection. What makes this technology truly remarkable is its ability to compensate for the natural variations in stone size and shape - a critical factor when working with such minute components. The system automatically adjusts each setting to ensure uniform appearance despite microscopic differences between individual stones.

Design possibilities have expanded exponentially with this technology. Jewelers can now create gradient color effects using thousands of differently hued stones, or produce photorealistic images through strategic stone placement. The density of stones achievable through automated micro-setting far surpasses what human hands could accomplish, allowing for unprecedented light play and visual depth. Some avant-garde pieces contain over 10,000 individually set stones in a single square centimeter.

Material science has played an equally important role in this advancement. New alloy formulations provide the necessary strength to maintain structural integrity despite the perforated nature of extensively micro-set pieces. The metal matrix must withstand daily wear while preserving the precise geometry of each setting - a challenge that has led to innovative metallurgical solutions combining precious metals with nano-reinforcements.

Quality control in nanometer-scale micro-setting represents another technological marvel. Automated inspection systems utilizing machine vision algorithms scan finished pieces at magnifications exceeding 500x, detecting any imperfections in stone alignment or setting security. This level of scrutiny ensures that each piece meets exacting standards before leaving the workshop, maintaining consistency across production runs.

The impact on jewelry design aesthetics has been profound. Designers now work with digital modeling software that simulates light interaction across micro-set surfaces, allowing them to preview visual effects before physical production begins. This digital workflow has given rise to entirely new design languages in jewelry, with patterns that play with optical illusions and light diffraction at microscopic scales.

From a manufacturing perspective, the technology has redefined production timelines. What once required weeks of painstaking handwork can now be accomplished in hours with superior precision. However, this doesn't eliminate the artisan's role but rather transforms it. Master jewelers now oversee the creative process at a higher level, programming intricate patterns and making artistic decisions about stone selection and arrangement that the automated systems then execute.

The commercial implications are equally significant. Micro-set jewelry commands premium pricing due to its technical sophistication and visual impact. Consumers increasingly seek out these pieces as wearable technology that represents the pinnacle of human craftsmanship enhanced by cutting-edge engineering. The market has responded with growing demand for these miniature masterpieces across all jewelry categories from watches to statement necklaces.

Looking ahead, the technology continues to evolve. Researchers are working on even smaller scale applications that could see gemstones measuring just 0.2mm being automatically set. Other developments focus on creating dynamic micro-set surfaces where stones can move or change position, adding kinetic elements to jewelry design. As the boundaries of what's possible continue to expand, one thing remains certain: nanometer-scale micro-setting has permanently altered the landscape of fine jewelry manufacturing.

For collectors and connoisseurs, these advancements represent an exciting new chapter in jewelry history. The pieces created through this technology will likely become the heirlooms of tomorrow, cherished not only for their beauty but as representations of a technological revolution in an ancient craft. As the technology becomes more widespread, we can expect to see its influence spread across all price points, making the magic of micro-setting accessible to broader audiences while maintaining its aura of exclusivity and innovation.

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025