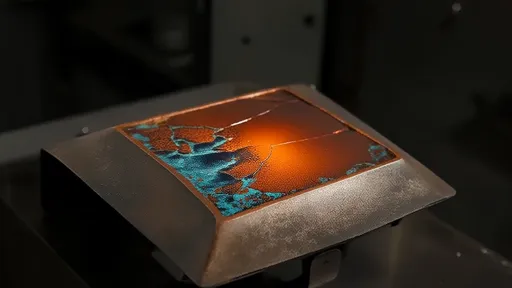

The art of investment casting, particularly the lost-wax method, has been refined over centuries to achieve precision and detail in metalwork. Among the critical factors influencing the quality of the final cast is the preparation of the mold material, often plaster. Recent advancements and empirical studies have highlighted the importance of optimizing the water-to-plaster ratio, with a particular focus on the 1.3:1 mix as a potential benchmark for achieving superior results.

The Science Behind the Ratio

Plaster molds in investment casting serve as the foundation for capturing intricate details before the molten metal is poured. The consistency of the plaster mixture directly impacts the mold's strength, porosity, and ability to replicate fine features. A ratio of 1.3 parts water to 1 part plaster by weight has emerged as a promising formulation. This balance ensures adequate fluidity for pouring while maintaining structural integrity during the burnout phase when the wax is melted away.

Too much water weakens the mold, leading to cracks or deformities, while too little results in a mixture that is difficult to work with and may trap air bubbles. The 1.3:1 ratio strikes a delicate equilibrium, allowing the plaster to flow smoothly into the wax pattern's crevices without compromising the mold's durability. This optimization is especially crucial for complex geometries or thin-walled designs where precision is non-negotiable.

Practical Implications for Foundries

Implementing this optimized ratio requires careful measurement and mixing techniques. Foundries adopting the 1.3:1 standard report fewer defects in their casts and a reduction in post-processing labor. The mixture's consistency ensures even distribution around the wax model, minimizing the risk of voids or uneven surfaces that could mar the final product.

Moreover, this ratio has shown compatibility with various types of casting plasters, including those enhanced with additives like silica or fiber reinforcements. The versatility of the 1.3:1 mix makes it adaptable to different project requirements without necessitating extensive recalibration of existing workflows. For artisans and industrial manufacturers alike, this translates to both time savings and material efficiency.

Challenges and Considerations

While the 1.3:1 ratio presents clear advantages, its success hinges on environmental factors such as temperature and humidity. Seasonal variations can affect the plaster's setting time and workability, necessitating slight adjustments in water content or mixing duration. Experienced technicians often rely on visual and tactile cues—such as the mixture's viscosity and sheen—to fine-tune the ratio for optimal performance under current conditions.

Another consideration is the plaster's curing process. The 1.3:1 mixture typically requires a controlled drying environment to prevent warping or premature dehydration. Proper ventilation and consistent temperatures help ensure that the mold achieves its full strength before being subjected to the high heats of metal casting.

Future Directions in Mold Optimization

As additive manufacturing and digital modeling continue to influence traditional casting methods, the role of material science in mold preparation grows increasingly sophisticated. Researchers are exploring how nanoparticles or alternative binders could further enhance plaster performance when used with the 1.3:1 ratio. These innovations aim to push the boundaries of what's possible in terms of detail resolution and production speed.

Meanwhile, the foundry industry's shift toward sustainability has prompted investigations into recycled or bio-based plasters that maintain performance at the optimized water ratio. Such developments could reduce the environmental footprint of investment casting without sacrificing quality—a win-win for manufacturers and ecologically conscious consumers.

The 1.3:1 water-to-plaster ratio represents more than just a technical specification; it embodies the marriage of empirical knowledge and modern material science. By continuing to refine and adapt this balance, the ancient craft of lost-wax casting enters a new era of precision and reliability.

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025