The world of fine jewelry has always been a realm where tradition meets innovation. Among the most fascinating developments in recent years is the marriage of ancient gold craftsmanship with cutting-edge nanotechnology, particularly in the realm of wear-resistant coatings. This fusion has given rise to a new generation of jewelry that honors the past while embracing the durability demands of modern life.

Ancient goldsmithing techniques, passed down through generations, have long been revered for their intricate detailing and unparalleled artistry. From the hand-hammered textures of Byzantine jewelry to the delicate filigree work of Etruscan artisans, these methods created pieces that were as much works of art as they were adornments. However, the soft nature of pure gold meant that these masterpieces were often fragile, susceptible to scratches and deformation over time.

Enter nanotechnology - the science of manipulating matter at the atomic and molecular scale. Researchers in materials science have developed ultra-thin, transparent coatings that bond at the molecular level with gold surfaces. These nanocoatings, typically measuring between 20 to 100 nanometers in thickness (about 1/1000th the width of a human hair), create an invisible shield that dramatically enhances the hardness of gold jewelry without altering its appearance or chemical composition.

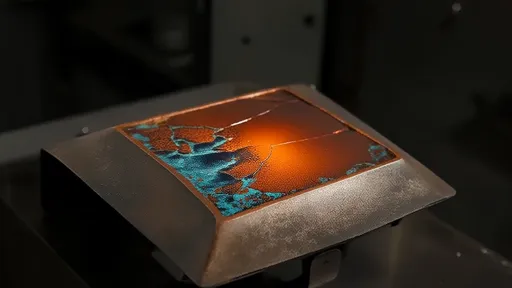

The application process itself is a careful balance between old and new. Master jewelers begin by crafting pieces using traditional techniques - lost-wax casting, hand engraving, or granulation. The finished pieces then undergo a specialized cleaning process to ensure perfect surface preparation before entering a vacuum chamber where the nanocoating is applied through advanced deposition techniques. This meticulous approach ensures that every microscopic detail of the original craftsmanship remains visible and untouched.

What makes these nanocoatings remarkable is their ability to mimic the natural oxide layer that forms on gold, but with far greater durability. Where traditional gold develops a patina over time through microscopic wear, the nanocoating maintains the original luster indefinitely. Laboratory tests have shown that treated pieces can withstand up to 8 times more abrasion than untreated gold before showing visible signs of wear, making them ideal for everyday jewelry that maintains its heirloom quality.

The implications for jewelry conservation are profound. Museums and private collectors are beginning to adopt this technology to protect priceless antique pieces without compromising their historical integrity. Unlike conventional plating methods that can alter surface characteristics or require periodic reapplication, nanocoatings provide permanent protection while being completely reversible by specialists if needed for restoration purposes.

From a consumer perspective, this technology addresses one of the primary concerns about fine jewelry ownership: the anxiety of damaging precious pieces. A 24-karat gold ring that would traditionally be reserved for special occasions can now be worn daily without fear of scratching or denting. This has led to a resurgence in demand for higher karat gold jewelry, as the technology removes the practical barriers that previously drove consumers toward harder but less pure alloys.

The environmental impact of this innovation shouldn't be overlooked either. By significantly extending the lifespan of gold jewelry, nanocoatings reduce the need for frequent repairs, replating, or replacement - all processes that carry environmental costs. Furthermore, the coatings themselves are typically composed of biocompatible materials that pose no health risks, addressing concerns about nanotechnology in wearable items.

Looking ahead, researchers are exploring ways to enhance these coatings with additional functionalities. Some experimental formulations incorporate hydrophobic properties to repel oils and prevent tarnishing, while others are being developed with self-healing capabilities to automatically repair microscopic scratches. There's even work being done on coatings that can change their optical properties in response to environmental stimuli, potentially creating jewelry that can alter its appearance on command while maintaining the feel of solid gold.

As with any technological advancement in a tradition-bound industry, acceptance has been gradual but steady. Master goldsmiths initially skeptical about "altering" their creations have come to appreciate how the coatings preserve rather than change their work. Consumers, once wary of anything "nano" in their jewelry, have embraced the practical benefits after seeing the results firsthand. Industry analysts predict that within the next decade, nanocoated gold jewelry will transition from a premium option to standard practice for high-end pieces.

This convergence of ancient artistry and space-age technology represents more than just a technical achievement - it's a philosophical bridge between jewelry's enduring role in human culture and our contemporary expectations of functionality. By solving gold's age-old durability dilemma without compromising its essential nature, nanocoatings have ensured that the legacy of fine gold craftsmanship can continue to shine brightly for generations to come, quite literally preserving the gleam of history while meeting the demands of modern life.

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025