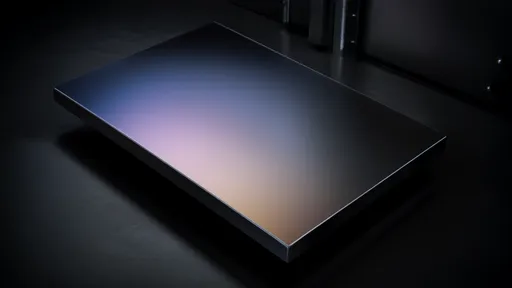

In the realm of material science and surface engineering, titanium stands out for its unique combination of strength, lightness, and biocompatibility. Among its most captivating properties is the ability to develop vibrant, iridescent colors through anodization—a process that has fascinated engineers, artists, and designers alike. While basic anodization techniques have been widely documented, recent advancements have pushed the boundaries of precision, enabling the creation of stunning gradient iridescence through meticulous voltage control. This breakthrough not only enhances aesthetic applications but also opens new doors for functional uses in industries ranging from aerospace to medical devices.

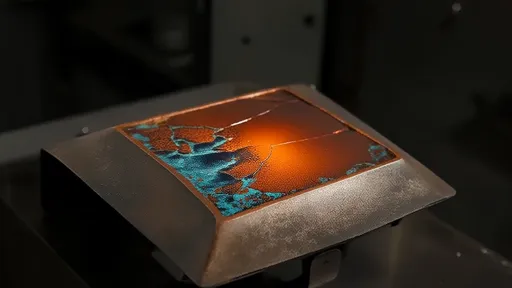

The fundamental principle behind titanium anodization lies in the formation of a thin oxide layer on the metal's surface when subjected to an electric field in an electrolytic solution. This oxide layer interferes with light, producing colors that vary with its thickness. Traditionally, achieving a specific color involved setting a fixed voltage, resulting in a uniform hue. However, the pursuit of gradient effects—where colors transition smoothly across the surface—requires a dynamic approach to voltage application. This is where precision voltage modulation comes into play, transforming a straightforward process into an art form guided by exact science.

At the heart of this advancement is the development of sophisticated power supply systems capable of delivering finely tuned voltage ramps. Unlike static voltage settings, these systems allow for real-time adjustments, incrementally increasing or decreasing the voltage to grow the oxide layer at varying rates. The relationship between voltage and oxide thickness is linear and predictable; typically, an increase of about 1 volt results in a thickness change of approximately 1.5 to 2 nanometers, which corresponds to a shift in the perceived color. By programming specific voltage profiles—such as linear, logarithmic, or custom curves—technicians can engineer color gradients that flow from one end of the spectrum to another, creating mesmerizing虹彩效果 that appear almost holographic.

One of the critical challenges in achieving perfect gradients is maintaining consistency across the entire surface of the titanium piece. Factors such as electrolyte concentration, temperature, and the geometry of the part can influence the uniformity of the oxide layer. To address this, researchers have integrated feedback mechanisms into the anodization process. Sensors monitor parameters like current density and pH levels, allowing the system to make micro-adjustments to the voltage in real time. This closed-loop control ensures that even complex shapes receive an even application of the oxide layer, preserving the integrity of the gradient without blotches or banding.

The applications of gradient anodization extend far beyond mere decoration. In the medical field, for instance, titanium implants with color-coded surfaces can indicate different sizes or types during surgery, reducing errors and improving efficiency. The oxide layer also enhances corrosion resistance and biocompatibility, making it doubly beneficial. In aerospace, components with gradient anodization can be used for part identification or to denote areas with specific thermal or electrical properties. Even in consumer electronics, this technology offers a way to create unique, customizable外观 that appeal to aesthetics-conscious customers.

Artists and jewelers have eagerly adopted these advanced techniques to produce one-of-a-kind pieces that play with light and color. By manipulating voltage with the precision of a painter's brush, they can create patterns that mimic natural phenomena like sunsets, ocean waves, or auroras. The ability to control gradients with such accuracy has turned titanium into a medium for high art, where the metal's surface becomes a canvas for optical innovation. Exhibitions featuring anodized titanium artwork have drawn attention for their vibrant, shifting colors that change with the viewer's perspective.

Looking forward, the future of titanium anodization appears bright with possibilities. Researchers are exploring the integration of digital design tools with anodization equipment, allowing for the direct translation of digital patterns into voltage protocols. This could enable mass customization, where each product receives a unique gradient based on a digital file. Additionally, there is growing interest in multi-step anodization processes, where layers are built up at different voltages to create even more complex optical effects. Some experiments involve combining anodization with other surface treatments, such as laser etching, to produce hybrid textures that enhance both function and form.

Despite these exciting developments, the practice of precision voltage control requires a deep understanding of both the equipment and the material. It is not merely about turning knobs but about comprehending the electrochemical reactions at play. Training and expertise remain crucial, as even minor deviations can lead to inconsistent results. However, as technology becomes more accessible and user-friendly, we can expect broader adoption across various sectors, democratizing the ability to create stunning虹彩效果 on titanium.

In conclusion, the advancement from static to dynamic voltage control in titanium anodization represents a significant leap in surface engineering. By harnessing precise voltage modulation, professionals can now generate gradient iridescence with remarkable accuracy, expanding the utility and appeal of titanium in numerous fields. This fusion of science and art not only meets practical demands but also inspires creativity, proving that even the most industrial processes can yield beautiful outcomes. As techniques continue to evolve, the rainbow-like possibilities on titanium are limited only by the imagination.

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025