The world of gemstone cutting has long been a delicate dance between artistry and precision. Among the various techniques employed, waterjet cutting stands out as a particularly fascinating method, combining the raw power of water with the finesse required for gemstone work. Recent advancements in this technology have pushed the boundaries of what was once thought possible, achieving tolerances as tight as ±0.003mm – a figure that would make even the most seasoned jewelers raise their eyebrows.

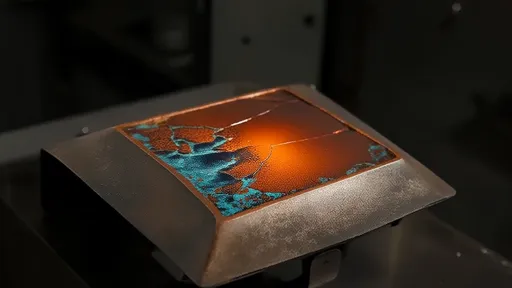

At the heart of this technological marvel lies a simple yet profound principle: using ultra-high-pressure water, often mixed with abrasive particles, to slice through materials with incredible accuracy. What makes this particularly remarkable for gem cutting is the complete absence of heat-affected zones, a common drawback in traditional laser or mechanical cutting methods. The cold-cutting process preserves the structural integrity of precious stones, maintaining their natural brilliance without introducing thermal stress fractures.

The journey to achieving such remarkable precision hasn't been without its challenges. Early waterjet systems, while revolutionary for industrial applications, lacked the finesse required for gem-quality work. The breakthrough came through a combination of advanced nozzle designs, sophisticated motion control systems, and real-time monitoring technologies. Modern systems can now maintain water pressure stability within 0.1% of the target value, a critical factor when working with materials where a fraction of a millimeter makes all the difference between a masterpiece and scrap.

Gemologists have particularly welcomed this technology for handling sensitive materials like emeralds, which are notoriously prone to cracking during conventional cutting. The waterjet's ability to follow complex three-dimensional paths with sub-millimeter precision has opened new possibilities in gem design. Intricate patterns and unconventional shapes that were previously either impossible or prohibitively expensive to produce can now be achieved with relative ease.

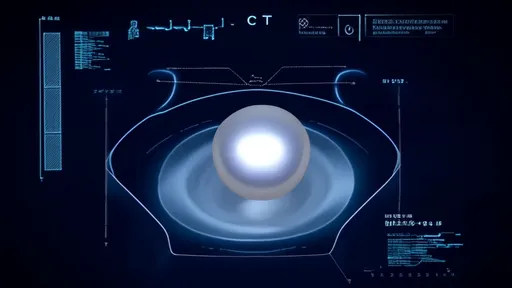

What truly sets apart the latest generation of waterjet systems is their integration with advanced imaging and computational modeling. Before the cutting begins, high-resolution 3D scans of the rough stone are analyzed by specialized software that determines the optimal cutting path to maximize both yield and aesthetic appeal. This digital approach minimizes human error and allows for precise execution of designs that would challenge even the steadiest of human hands.

The implications of this precision extend beyond mere technical achievement. In the world of high-end jewelry, where uniqueness and perfection command premium prices, the ability to consistently produce flawless cuts with such exacting tolerances represents a significant competitive advantage. Designers are no longer constrained by the limitations of traditional cutting wheels and can experiment with bold new forms that showcase gems in ways previously unimaginable.

As with any disruptive technology, the adoption of ultra-precise waterjet cutting hasn't been without controversy. Some purists argue that it removes the "human touch" from gem cutting, while others see it as merely another tool in the artisan's kit – albeit an extraordinarily precise one. What's undeniable is that it has permanently altered the landscape of gemstone processing, setting new standards for what constitutes precision in this ancient craft.

Looking ahead, the technology continues to evolve. Researchers are working on even finer abrasive mixtures and more stable pressure delivery systems that could potentially push precision beyond current limits. As these systems become more accessible, we may see a new era in gem cutting where such extreme precision becomes the norm rather than the exception, changing our very definition of what's possible in stone cutting and jewelry making.

The ±0.003mm tolerance represents more than just a number – it's a testament to human ingenuity in our perpetual quest to shape nature's treasures with ever-greater perfection. As waterjet technology continues to mature, its impact on the gem and jewelry industry promises to be as multifaceted as the stones it helps create.

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 27, 2025

By /Aug 19, 2025